Phone:

+86 13828 600940

Physical address:

No.8Liyuan Road, Bogang community, Shajing Street Baoan District, Shenzhen, China

The use of checking fixtures in manufacturing industries plays a crucial role in ensuring product quality, consistency, and efficiency throughout the production process. Checking fixtures are specialized tools and devices designed to verify and validate the dimensional accuracy and functionality of various components and assemblies. They provide manufacturers with a reliable means of quality control, reducing defects, minimizing rework, and saving time and resources. This article aims to explore the different types of checking fixtures utilized in manufacturing industries, highlighting their key functions, benefits, and real-world applications. By understanding the diverse range of checking fixtures available, manufacturers can make informed decisions about implementing the most suitable fixtures to enhance their production processes and product quality.

Checking fixtures, also known as inspection fixtures or gauges, are an essential tool in the world of manufacturing. They provide a means to ensure that each produced component or assembled product meets the required specifications and quality standards. In simple terms, checking fixtures are like a custom-made template that allows manufacturers to accurately measure and verify the dimensional accuracy, alignment, and functionality of parts during production.

Checking fixtures play a crucial role in maintaining product quality and consistency. By using these fixtures, manufacturers can identify any deviations or defects early in the production process, preventing faulty products from reaching the market. Furthermore, checking fixtures help to streamline manufacturing processes by reducing the time and effort required for manual inspections. They also contribute to minimizing scrap and rework, saving valuable resources and increasing productivity.

2. Key Functions and Importance of Checking Fixtures

The primary function of checking fixtures is to ensure that each product or component meets the desired quality standards. By accurately measuring critical dimensions and tolerances, checking fixtures provide manufacturers with a reliable method to verify the conformity of parts during production. This not only prevents defective products from reaching customers but also maintains consistency in product quality.

Checking fixtures offer a significant advantage in terms of streamlining manufacturing processes. Instead of relying solely on manual inspections, which can be time-consuming and prone to human error, manufacturers can use these fixtures to perform measurements quickly and accurately. This allows for a more efficient production line, reducing the overall cycle time and increasing throughput.

One of the most frustrating and costly aspects of manufacturing is dealing with scrap and rework. Checking fixtures help minimize these issues by identifying defects and deviations early in the production process. By catching problems before they escalate, manufacturers can take corrective actions promptly, reducing the amount of scrap and rework required. This not only saves valuable resources but also contributes to a more sustainable and cost-effective manufacturing process.

Traditional checking fixtures are custom-made fixtures designed to fit specific parts or components. These fixtures are usually made from materials such as steel or aluminum and are manually operated. They are versatile and can accommodate various part geometries, making them suitable for a wide range of applications in manufacturing industries.

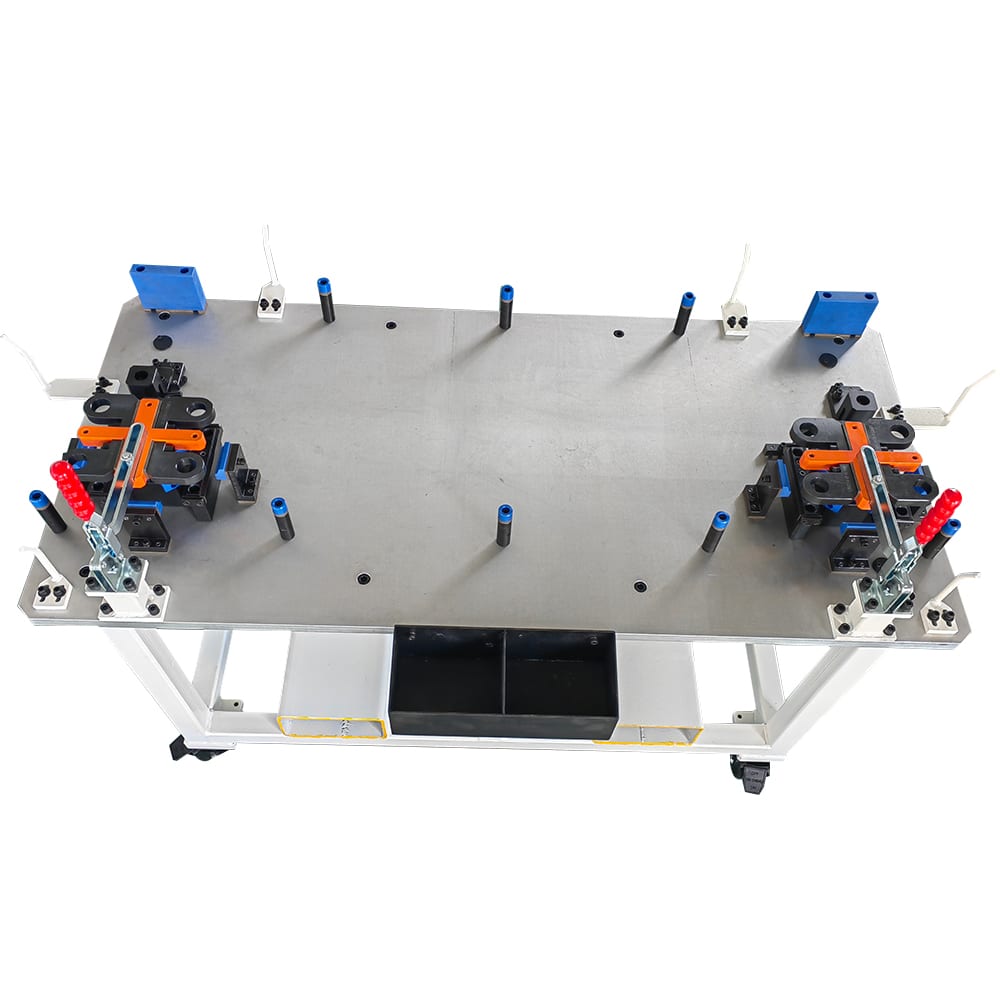

Modular checking fixtures offer increased flexibility and ease of use compared to traditional fixtures. They consist of standardized components that can be easily assembled and disassembled to adapt to different part configurations. This modular design allows manufacturers to quickly reconfigure the fixtures for different products, saving time and reducing costs associated with building new fixtures for each variation.

Coordinate Measuring Machine (CMM)-based checking fixtures utilize the precision of CMMs to perform accurate measurements. These fixtures incorporate CMM probes that can automatically measure multiple points on a part, providing highly detailed and precise data. CMM-based fixtures are commonly used in industries where tight tolerances and high accuracy are critical, such as aerospace and automotive manufacturing.

Hydraulic or pneumatic checking fixtures utilize hydraulic or pneumatic systems to apply controlled pressure or force to parts being tested. These fixtures are often used in applications where the functionality or strength of a part needs to be evaluated. By applying specific forces, manufacturers can simulate real-world conditions and verify the performance of components.

Specialized checking fixtures are designed for specific manufacturing processes or industries. These fixtures incorporate unique features or technologies to address specific measurement or testing requirements. For example, fixtures used in the electronics industry may include specialized connectors or contact points to ensure accurate electrical testing.

Modular checking fixtures offer several advantages over traditional fixtures. Their modular design allows for quick and easy reconfiguration, reducing the time and cost associated with building new fixtures for different part variations. Additionally, the standardized components of modular fixtures can be reused across multiple projects, maximizing their value and providing a cost-effective solution for manufacturers.

Modular checking fixtures typically consist of a base plate, standardized fixture elements (such as clamps, pins, and supports), and modular connection systems. These components can be easily assembled and disassembled to accommodate different part geometries. The modularity of these fixtures allows manufacturers to create customized setups for various product configurations without the need for extensive machining or fabrication.

Modular checking fixtures find applications in various industries, including automotive, consumer electronics, and appliance manufacturing. For example, in the automotive industry, modular fixtures are commonly used to verify the fit and alignment of body panels, ensuring precise assembly. In the consumer electronics industry, these fixtures aid in the testing and alignment of delicate components, ensuring optimal functionality.

With their versatility and efficiency, modular checking fixtures offer manufacturers a flexible and cost-effective solution to meet the demands of diverse production processes and evolving product designs.

When it comes to precision and accuracy, CMM-based checking fixtures take the cake. CMM stands for Coordinate Measuring Machine, and these fixtures use this sophisticated technology to ensure that each part is measured with superhuman precision.

CMM-based checking fixtures work by using a combination of precise sensors and computer algorithms to measure and compare parts to a digital model. The parts are placed on the fixture, and the CMM takes hundreds (sometimes thousands) of measurements to check if they align with the desired specifications.

The benefits of CMM-based fixtures in quality control are downright impressive. Firstly, their accuracy is unrivaled. With their ability to measure parts down to the tiniest fraction of a millimeter, you can rest assured that only the best parts make it through.

Secondly, CMM-based fixtures significantly speed up the inspection process. While manual inspections can take hours or even days, CMM-based fixtures can deliver results in a fraction of the time. This means more efficiency and less time spent waiting around for inspections to be completed.

Let’s take a look at a couple of case studies that demonstrate the power of CMM-based fixtures.

Case Study 1: XYZ Manufacturing Company

XYZ Manufacturing Company implemented CMM-based fixtures in their quality control process for automotive parts. With the help of these fixtures, they were able to reduce the rejection rate of their parts by 50%. Not only did this boost their reputation among clients, but it also saved them a substantial amount of money by minimizing waste.

Case Study 2: ABC Aerospace

ABC Aerospace faced a major challenge in ensuring the accuracy and safety of their aircraft components. By adopting CMM-based fixtures, they were able to identify and rectify potential issues before they caused any trouble. This proactive approach not only improved the overall quality of their products but also increased customer trust and satisfaction.

Looking for flexibility in your testing process? Look no further than hydraulic/pneumatic checking fixtures. These fixtures utilize the power of fluids (hydraulic or pneumatic) to apply controlled force or pressure on parts being tested.

The advantage of hydraulic/pneumatic fixtures lies in their ability to simulate real-life conditions while testing the parts. By applying precise forces or pressures, these fixtures can assess how a part performs under different practical scenarios.

One of the major advantages of using hydraulic/pneumatic systems is their adaptability. They can be easily customized to test a wide range of parts, making them ideal for manufacturers dealing with diverse product lines. Whether you’re testing small electronic components or heavy-duty machinery, hydraulic/pneumatic fixtures can handle it all.

Another advantage is their speed. These fixtures can test parts rapidly, allowing for quick identification of defects or performance issues. This not only saves time but also reduces the chances of faulty parts making it through to the next stage of the production process.

Hydraulic/pneumatic fixtures find applications in various industries, from automotive to aerospace and everything in between. For example, in the automotive industry, these fixtures are used to test the durability and functionality of suspension systems, ensuring that vehicles can handle different road conditions.

In the aerospace industry, hydraulic/pneumatic fixtures are employed to simulate the extreme conditions experienced during flight. By subjecting components to varying pressures, these fixtures ensure that they can withstand the demands of high-altitude environments.

Creating an effective checking fixture requires careful consideration of design principles. The fixture should be designed in such a way that it securely holds the part being tested while providing easy access for inspection. It should also be built to withstand the forces and pressures applied during testing without compromising accuracy.

When it comes to materials, durability and stability are key. Choosing materials that can withstand repetitive use and environmental conditions is crucial. Additionally, construction techniques such as precision machining and welding should be utilized to ensure the fixture’s integrity and accuracy.

Last but not least, ergonomics and operator considerations should not be overlooked. The fixture should be designed with the operator’s comfort and safety in mind. Easy-to-use controls, clear visual indicators, and ergonomic positioning of critical elements can significantly improve the efficiency and user experience of the checking fixture.

So, the next time you encounter a checking fixture, remember that there are various types available, each serving a unique purpose. From CMM-based fixtures for precision and accuracy to hydraulic/pneumatic fixtures for flexibility, the world of checking fixtures offers a solution for every manufacturing need.In conclusion, checking fixtures are indispensable tools in the manufacturing industry that enable companies to ensure high-quality products, streamline processes, and minimize errors. By exploring the various types of checking fixtures available, such as modular fixtures, CMM-based fixtures, and hydraulic/pneumatic fixtures, manufacturers can choose the best option for their specific needs. Additionally, considering design considerations and real-world case studies further enhances the understanding and implementation of checking fixtures. Incorporating the right checking fixtures in manufacturing processes can lead to improved efficiency, increased productivity, and enhanced customer satisfaction. By staying abreast of the latest advancements and utilizing appropriate checking fixtures, manufacturers can continue to deliver superior products while maintaining a competitive edge in the market.

Checking fixtures serve the purpose of verifying and validating the dimensional accuracy and functionality of various components and assemblies in the manufacturing process. Their main goal is to ensure product quality, consistency, and efficiency while minimizing defects and rework.

Yes, checking fixtures can be customized to specific manufacturing needs. Modular checking fixtures, for example, offer versatility and can be easily adjusted or reconfigured to accommodate different parts or products. Additionally, specialized checking fixtures can be designed and built to meet the unique requirements of specific manufacturing processes.

CMM-based checking fixtures utilize Coordinate Measuring Machines (CMMs) to accurately measure and inspect parts and assemblies. This technology allows for precise and repeatable measurements, ensuring that products meet the required specifications. By relying on CMMs, manufacturers can achieve higher levels of precision, accuracy, and quality control in their production processes.

When designing checking fixtures, several factors should be considered. These include the specific requirements of the part or product being manufactured, material selection for the fixture to match the part’s characteristics, construction techniques for durability, ergonomic considerations for operator ease of use, and overall manufacturability to ensure the fixture can be efficiently produced and maintained. Taking these factors into account helps in creating effective and reliable checking fixtures.