Phone:

+86 13828 600940

Physical address:

No.8Liyuan Road, Bogang community, Shajing Street Baoan District, Shenzhen, China

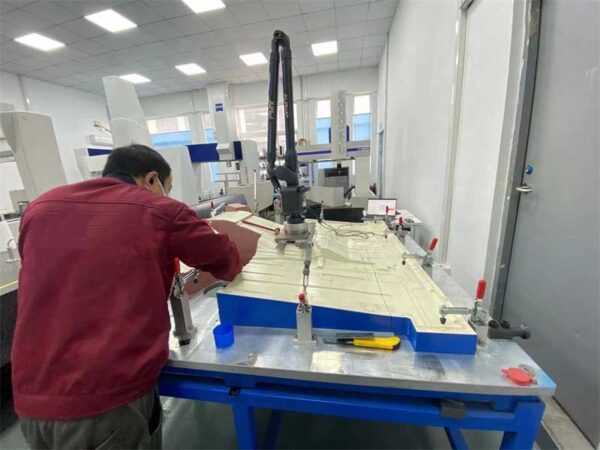

High Precision Measurement: providing precise measurements up to 0.01mm or 0.00005 inches respectively.

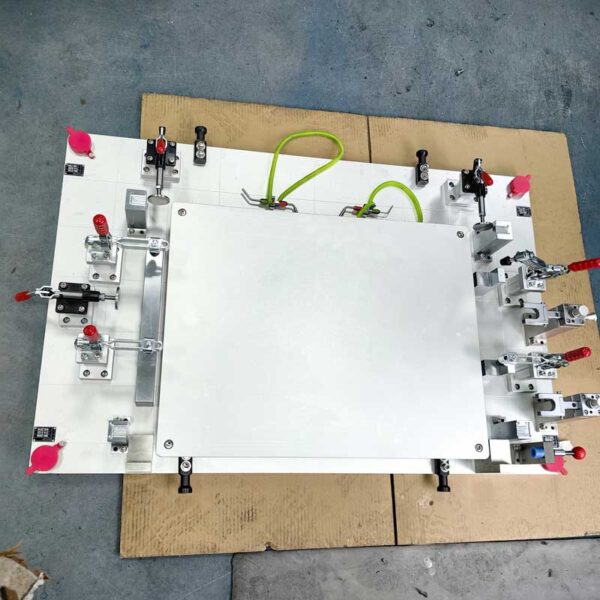

| Model Number | FM-AJ-01 |

| Processing Technology | CNC Machining |

| Material Capabilities | Aluminum, Brass, Bronze, Copper, Hardened Metals, Stainless steel, Steel Alloys |

| Place of Origin | Shenzhen China |

| Type | Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM |

| Micro Machining or Not | Micro Machining |

| Brand Name | Favamill |

| Product name | Measuring fixture |

| Application | Auto Checking Fixture |

| Material | Aluminum, stainless steel, iron, alloy etc. |

| Surface treatment | Customer Requirements |

| Quality control | 100% detection(CMM) |

| Sample | Support |

| Selling Units: | Single item |

| Single package size: | 10X10X10 cm |

| Single gross weight: | 0.300 kg |

Here are five features on our fixtures.

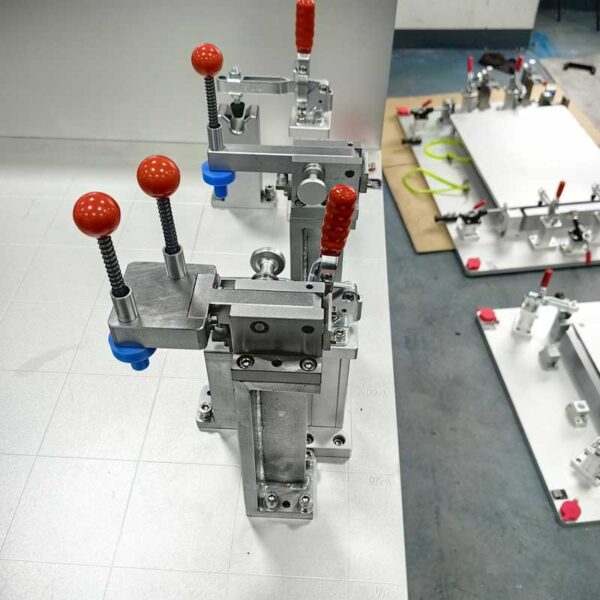

1. Precision Machining: CNC Machining offers high precision and accuracy.

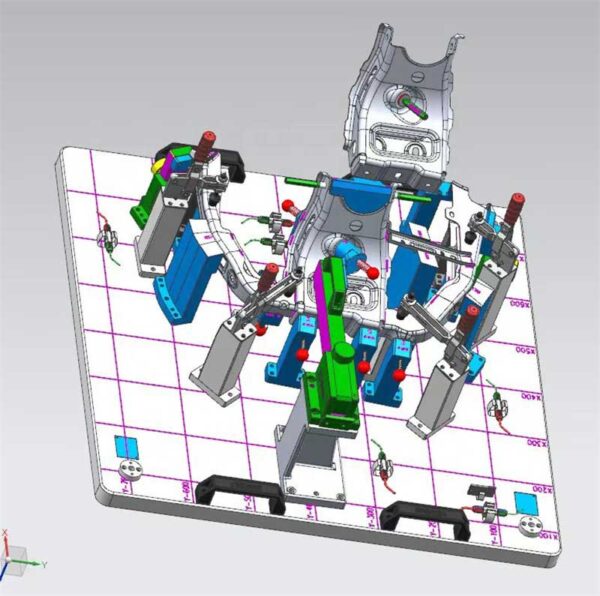

2. Custom-Designed: Designed specifically to inspect specific parts or assemblies such as body panels, chassis parts or engine components in-depth.

3. Modular Construction: Modular designs for easy reconfiguration and adaption to different vehicle models or part variants on production lines.

4. Integral Measuring Systems: Integrating measurement systems like precision gauges, dial indicators or CMM probes in order to streamline part inspection for accurate and efficient part verification.

5. Sturdy Materials:

Here are five features on our fixtures.

1. Precision Machining: CNC Machining offers high precision and accuracy.

2. Custom-Designed: Designed specifically to inspect specific parts or assemblies such as body panels, chassis parts or engine components in-depth.

3. Modular Construction: Modular designs for easy reconfiguration and adaption to different vehicle models or part variants on production lines.

4. Integral Measuring Systems: Integrating measurement systems like precision gauges, dial indicators or CMM probes in order to streamline part inspection for accurate and efficient part verification.

5. Sturdy Materials: Constructed of hardy, sturdy materials such as aluminum, steel or composite to withstand the rigorous manufacturing environment and offer long-term reliability.