Phone:

+86 13828 600940

Physical address:

No.8Liyuan Road, Bogang community, Shajing Street Baoan District, Shenzhen, China

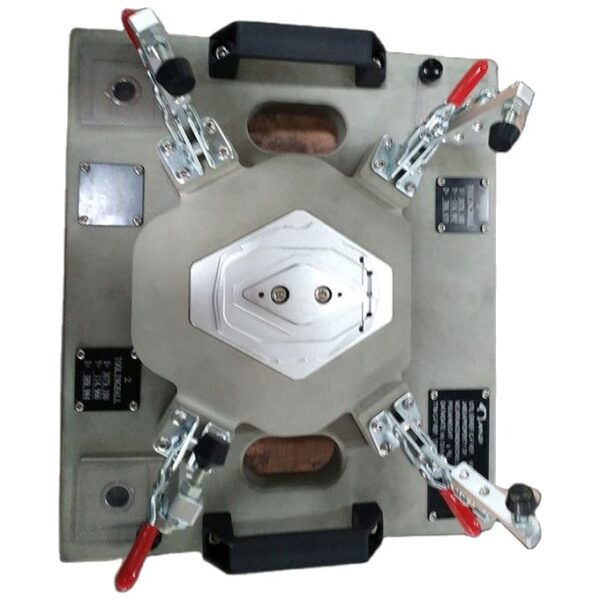

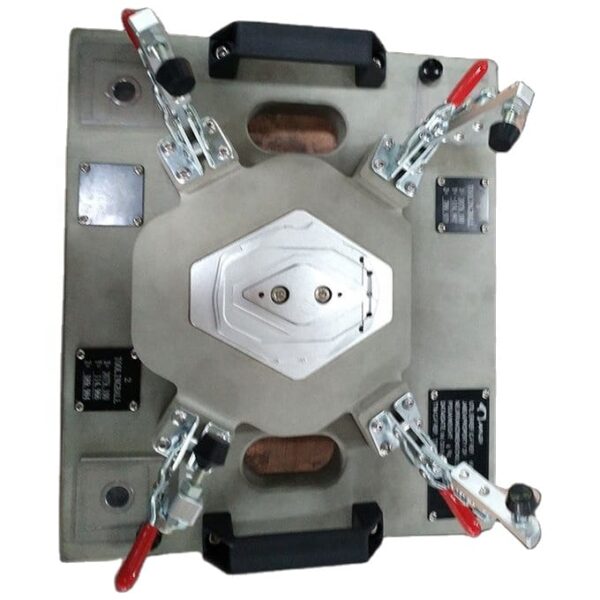

Overall, this automobile rear door welding assembly fixture should provide precise alignment, secure clamping, and efficient welding processes to maintain consistent quality while improving productivity and accelerating manufacturing processes.

| Brand Name | Favamill |

| Product Name | Welding Assembly Fixture For Automobile Rear Door |

| Tolerance | ±0.002mm |

| Material | SKD11, SKD 61, Cr12MOV, D2, SKH-9, RM56, ASP23 etc. |

| Design Software | AutoCAD, Solid works, PRO/E, UG |

| Standard | ISO9001 |

| Mould Type | Compound Stamping Die, Single Stamping Die, Progressive die or according to Customer’s requirements |

| First Trial | 15-25 days after mold drawing confirmed |

| Mould Life | Depends on customer’s production capacity |

| Quality confirm | Can send strip layout of die, testing video, inspection certificate and sample of product |

| Package | PE bags and carton for products, wooden case for Die/mold, or as customer’s requirements |